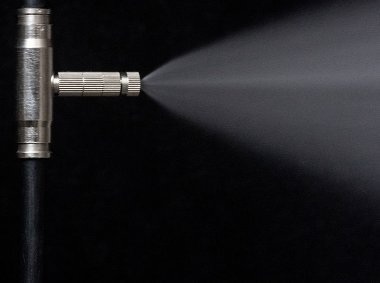

When connected to a special high-pressure pump, water is forced through our atomizing nozzle and rapidly atomized into droplets as small as 5-10 millionths of a meter (5-10 microns). The spray system creates billions of tiny droplets that quickly evaporate. This evaporation process requires energy, which is extracted from the air as heat. To achieve a cooling effect. This is the most commonly used spray system. When placed in an enclosed area with limited air exchange, such as a factory or greenhouse, the nebulizing system will continue to increase humidity levels in the environment. Humidity levels can be as high as 90% or more. This makes the spray system ideal for humidification....